In Germany, laws, regulations and standards govern the use and quality of fall protection systems for pitched and flat roofs. This is intended to help prevent serious accidents. It is often difficult for laypersons to find their way through the vastness of these regulations, as some of them build on or complement each other. In the following, we will give you a brief overview of the most important regulations. These should help those responsible to select the appropriate protective measures.

The Occupational Health and Safety Act

In brief:

The ArbSchG protects employees in the workplace through obligations for employers (e.g. risk assessment) and rights for employees (e.g. safe workplace).

In detail:

Sections 3 and 4 of the Occupational Health and Safety Act of 1996 contain statements on the employer's general obligations (Section 3) and the general principles (Section 4) for improving safety.

For example, §3 ArbSchG states: ‘The employer is obliged to take the necessary occupational health and safety measures, taking into account the circumstances that affect the safety and health of employees at work’.

In §4 of the general principles, particular attention should be paid to the following sentence: ‘[...] individual protective measures are subordinate to other measures [...]’. This gives collective protection greater importance than individual protection.

Ordinance on Industrial Safety and Health (BetrSichV)

In brief:

In Germany, the BetrSichV regulates the basic requirements for the safety of work equipment in order to protect the safety and health of employees.

In detail:

The very general provisions of the Occupational Health and Safety Act are specified in more detail by the provisions of the Ordinance on Industrial Safety and Health (BetrSichV of 2002).

In Annex 2, Section 5 of the BetrSichV, there are various references to the use of collective fall protection and fall arrest systems. The nature of fall protection devices is also explained here: ‘[...] Where necessary, provision must be made for the installation of fall protection devices. These devices must be designed and constructed in such a way that falls are prevented and injuries to employees are avoided as far as possible. The collective fall protection devices may only be interrupted at access points to ladders or stairs.’

Technical rules for operational safety (TRBS2121/ 2007)

The technical rules for operational safety once again emphasise the priority of collective measures over individual measures. However, they also provide additional information on the order in which the safety measures should be selected: for example, fall protection systems take precedence over fall arrest systems, which in turn take precedence over individual protective measures.

Further information can be found in our article TRBS 2121: Technical rules for operational safety.

Workplace directive (ASR A2.1/ 2012)

The Workplace Directive deals in detail with the question of the height above which fall protection measures must be taken. For example, it stipulates that a railing must be installed if there is a risk of falling or that openings in walls and floors must be adequately covered. Further information on this can be found in our article ASR A2.1.

Accident prevention: German Social Accident Insurance (DGUV)

Specific standards for fall protection can also be found in other places. For example, DGUV regulation 38 is also appropriate and dedicates a separate section to fall protection in §9. § Section 9 Fall protection: This section of DGUV Regulation 38 specifies the requirements for fall protection on construction sites. It covers the following topics, among others:

General requirements for fall protection

Personal protective equipment against falls from a height (PPE)

Collective protective measures against falls from a height

Special requirements for fall protection when working on roofs

Annex 3 Fall protection: Annex 3 of DGUV Regulation 38 contains supplementary information and notes on fall protection, e.g. calculation methods for fall protection and selection criteria for PPE against falls from a height.

When is fall protection required by law?

Various regulations clearly define when there is a risk of falling and what protective measures must be taken to protect the life and health of employees.

In principle, the following applies: Falling edges that are higher than 1 metre above the ground are already considered a hazard. On flat roofs, additional safety measures are only mandatory from a height of 3 metres. However, there are exceptions: For short periods of work with low hazard potential, fall protection can be dispensed with if other suitable protective measures are taken, such as the use of personal protective equipment (PPE). Under certain conditions, temporary work on fall edges can be carried out without fall protection if suitable safety measures, such as barriers, are in place.

Fall protection on flat roofs: The STOP principle in action

The STOP principle is applied when selecting fall protection for flat roofs. It prioritises technical, organisational and personnel measures in this order:

1. substitution

Substitution, or replacing sources of danger, is the most effective protective measure. For example, can roof access involving a risk of falling be reduced or avoided?

2. technical measures (T):

Primary protective measure: Preference is given to fall protection in the form of parapets, defences or railings. These prevent access to the danger zone and provide collective protection.

2. organisational measures (O):

Secondary protective measure: If technical measures are not possible, fall arrest systems such as protective scaffolding, protective walls or safety nets are used. This is often the case for temporary work on the roof.

3. personal measures (P):

Last resort: Personal fall protection equipment (PPE) is only permissible if neither technical nor organisational measures can be implemented. This must be used correctly in order to provide effective protection. Regular instruction of employees is essential.

Fall protection in Germany: Who is responsible?

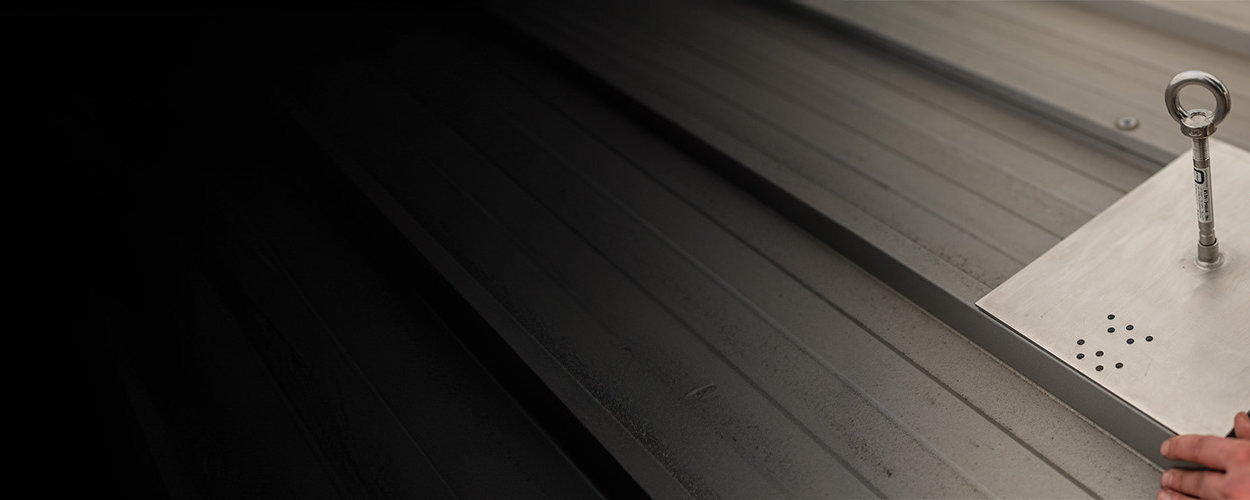

Fall protection must be taken into account as early as the construction planning stage in order to prevent accidents on building roofs. The flat roof guidelines of the Zentralverband des Deutschen Dachdeckerhandwerks regulate the anchoring of fall protection systems. According to the Workplace Ordinance and building regulations, building operators are responsible for roof safety, while employers must appoint a competent person to inspect the fall protection systems. Employees are obliged to co-operate in accordance with §15 ArbSchG and §21 Para. 1 SGB VII. When employing external companies, the commissioning employer remains ultimately responsible for the accident protection of its employees. In the private sector, the building owner bears responsibility. To summarise, the primary responsibility lies with building operators and employers, the inspection is carried out by competent persons, and employees as well as commissioning employers and building owners in the private sector have specific obligations to cooperate.

Fall protection on construction sites: Regular inspections are mandatory!

Implementing the legal requirements for fall protection on construction sites is not enough. In order to ensure the safety of employees, fall protection systems must be inspected regularly. This includes an annual inspection requirement in which all fall protection equipment must be thoroughly inspected at least once a year.

Prerequisites:

Conformity to standards: The products used must fulfil the legal standards.

Labelling: Safety barriers must be labelled with the following information:

Test centre number

Year of production

Valid serial number

The fall protection systems may only be inspected by qualified persons, which may also include external service providers. The installation of the safety barriers must also be carried out by specialised personnel in order to ensure safety. There is also a documentation obligation: all inspections and safety measures must be carefully documented and documented with photos. This documentation is important evidence in the event of an accident, for example for insurance purposes.